Managing workplace hazards in the construction industry is a top priority every day because the working environment constantly changes. There are often many different contractors working alongside each other. It becomes more complex in multi-storey construction, where work is carried out over several levels. Injury and fatality rates in construction remain high.

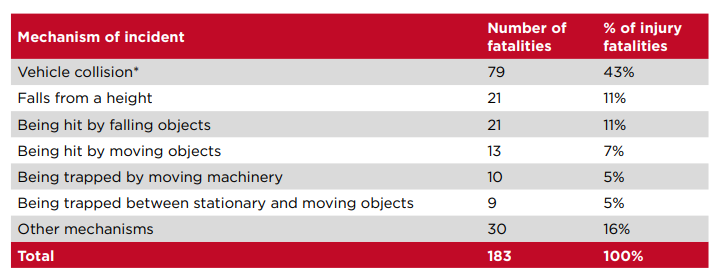

Safe Work Australia report that in 2013–14, the construction industry accounted for 9% of the workforce. However, the sector was responsible for 12% of the total work-related fatalities for that year. In 2012–13 the construction industry had the 4th highest injury rate. In 2013-14 the industry had the 5th highest fatality rate. The table below shows the main causes of injury and fatalities in the Australian construction sector between 2013-14.

When we compare these historical statistics with those released in 2020, we see some similar results, although there’s a jostle for first place. Vehicle collision has significantly overtaken falls from height, accounting for 43% of all injury fatalities. Being hit or trapped by objects or in moving machinery is the cause of 28% of workplace fatalities.

For this article, we discuss the top workplace hazards in the construction industry to guide your safety training themes.

The Four Main Causes of Fatalities

There are four main causes of fatalities due to workplace hazards in the construction industry. They are vehicle collisions, including the interaction between people and moving mobile plant, working at height, being hit by, or caught in, moving objects, and working and coming into contact with electricity.

1. Vehicle Collisions and Interaction with Mobile Plant

Maintaining effective exclusion zones between workers on foot and operating mobile plant is not only a challenge for construction companies but many other industries. Many workplaces use mobile plant such as forklifts and cranes. However, in the construction industry, this extends to larger machines, including excavators, diggers, loaders, trucks, rollers, water carts, and so on.

What Should be Done to Prevent Vehicle Collisions and Interaction With Mobile Plant?

When operating mobile equipment, you must be constantly aware of surrounding powered mobile plant and operators on foot. All mobile plant have blind spots or vision shadows. In respect of large powered mobile plant, you need to recognise that the operator’s view of other powered mobile plant or pedestrians may be restricted or even obscured by the machine itself.

If a worker is required to enter the plant operating zone to talk with the operator, then the powered mobile plant must be temporarily halted. Workers must:

- Make positive communication with the plant operator;

- Lower all ground engagement tools or implements to the ground;

- Disengage the plant controls to ensure inadvertent engagement cannot occur either directly by the operator or otherwise;

- Visibly remove their hands from the powered mobile plant’s controls; and

- Cease any motion of the plant.

Tap into Safety Mobile Plant Safety Training Courses

We have developed several out-of-the-box safety training courses to address the safety training theme of working around mobile plant hazards in the construction industry.

- People and Plant on a Construction Site

- Road Works Plant Exclusion Zones

- Access, Egress and Rollaways

- Traffic Management

- Forklift Operation

- Transport Chain of Responsibility

- Transport Chain of Responsibility for Leaders

- Mobile Cranes

- Excavations

- Access Egress Barrier Selection

- Blind Spots and Vision Shadows

Contact Us for more information.

See our article, The Compliance and Complacency of Using Forklifts.

2. Working at Height

A fall hazard is anywhere a person could fall from one level to another. Although fall hazards are more obvious in multi-story construction they are common on most construction sites. The height of a fall is not the only thing you should consider, e.g. you may survive a 2-metre fall onto the sand without any injury, but not survive a 1-metre fall onto a star picket.

Falls from height fatalities were 28% of all deaths in 2013-14. Of the fatalities caused by falls from height, 58% were from roofs and ladders. 50% of these involved falls of less than 4m.

What Should be Done to Prevent Falls From One Level to Another?

The construction industry is aware of the risks that working at height introduce and have some significant measures in place to reduce these risks.

- Edge protection which incorporates a guard rail, mid-rail and toe board must be provided to the edge of any scaffold platform, fixed stair, landing, suspended slab, formwork, or falsework where there is a risk of a person falling two or more metres.

- Edge protection should be provided where there is a risk that a person could fall three or more metres from an edge at the workplace other than an edge referred to in point 1 above.

- Where it is not practicable to provide edge protection as outlined in point 2 above then a fall injury prevention system should be provided and used to control the risk of a fall or a fall arrest system used to arrest a fall.

Tap into Safety Height Safety Training Courses

We have developed several out-of-the-box safety training courses to address working at height hazards in the construction industry.

- Working at Height in Commercial Construction

- Working at Height in Residential Construction

- Scaffold Erection and Top Floor

- Scaffold Hazard Awareness

- Work at Height Permit to Work

Contact Us for more information.

See our article, What Can We do to Prevent Fall From Height Risks

3. Being Hit by Moving Objects

Coming into contact with moving machinery, transported goods, and tools and equipment are critical workplace hazards in the construction industry that caused 14% of all injuries in 2013-14.

What Should be Done to Prevent Being Hit by Moving Objects?

There are ways that you can address this risk of injury and ensure good worker separation from moving objects. Always ensure that:

- Machine guarding is in place to prevent contact with moving parts.

- The correct isolation procedures are completed before any work is carried out on equipment with moving parts.

- Exclusion zones are established to make sure that load transport areas are sufficiently barricaded off to prevent workers from accessing the area.

- Tools, materials and equipment are secured to prevent them from falling to the level below and acting as projectiles.

Tap into Safety Training Courses That Address Falling Object Hazards

We have developed three out-of-the-box safety training courses that include training on the safety theme of falling objects.

- Stock Picking Warehouse

- Working at Height in Commercial Construction

- Scaffold Hazard Awareness

- General Safety Induction

4. Coming Into Contact With Electricity

Working in and around electricity creates significant workplace hazards in the construction industry. The industry uses electrical equipment and powered tools. These tools can be damaged and incur frayed leads.

What Should be Done to Prevent Coming Into Contact With Electricity?

Damaged power tools should be tagged out of service and no longer used until repaired or replaced.

There are many times that powerlines encroach working spaces mainly when mobile cranes are in use or scaffold is erected. Establish powerline corridors and do not breach minimum clearances. Activities that are at risk include:

- Drilling, excavating, loading, hauling, or dumping

- The construction, fabrication, maintenance or storage of buildings, structures, machinery, and equipment

- Operation of vehicles or machinery with elevating parts that do not afford the required clearance when fully raised

When lifting near overhead power lines, a minimum 6m safe distance must be maintained. If the crane boom is required to move closer to the power lines, then a Spotter must be in place to ensure that the boom remains a minimum of 3m away.

Use positive confirmation that de-energising has occurred before erecting scaffolds that are close to live lines. Scaffolds constructed of timber or other non-conductive materials should not be closer than 1.5 m to powerlines and scaffolds with metallic components should not be closer than 4m.

Tap into Safety Training Courses that Include Electrical Hazards

We have developed three out of the box safety training courses to address the safety training theme of working around electrical hazards in the construction industry.

Contact Us for more information, or if you’d like a custom-built module for your working around electrical hazards.

See our article, 8 Workplace Hazards That Can Kill

The Main Causes of Injuries in Construction

There are three leading causes of injuries due to workplace hazards in the construction industry. They are manual handling injuries, falls, slips and trips, and being hit by moving objects.

1. Body Stressing Through Manual Handling

Manual handling injuries continue to injure workers through poor choices of lifting items that are too heavy, lifting heavy items too often, and poor postures. Manual handling and body stressing can occur through prolonged sitting, long hours behind the wheel, and when completing manual and physical tasks.

What Should be Done to Prevent Manual Handling Injuries?

When lifting, eliminate the hazard where you can, by using mechanical aids or using a two-person lift. If you have to manually lift, eliminate the hazard by adopting correct manual handling techniques such as maintaining an S-curve to protect your spine and keeping your arms close to your body to protect your shoulders.

Before lifting equipment, ask yourself these questions:

- Must it be moved?

- Must it be lifted?

- Is the load too heavy to lift safely by hand?

- Can it be moved mechanically?

- Can the size or weight of the load be reduced?

- Can someone help you lift the load?

If you have to lift equipment manually, it is vital that you use the correct lifting technique, and warm up before you start. Ensure your knees remain behind your toes, so they’re in the ‘safe zone’. Your spine should be ‘neutral’ or ‘S-curved’ but NOT horizontal. You can achieve this through ‘hinging at the hips’ or moving your ‘butt back’.

Lift to waist height keeping the load close to your body. Remember to point your nose and toes in the same direction when lifting and try not to twist your body when carrying loads.

Tap into Safety Manual Handling Training Courses

We have developed several out of the box safety training courses to address safe manual handling.

- Manual Handling

- Overhead Electrical Work

- Manual Handling in the Warehouse

- Manual Handling in the Maintenance Workshop

- Manual Handling in the Transmission Yard

- Installation of Underground Power Lines

- Safe Manual Handling

Contact Us for more information.

See our article, Manual Handling Injuries Are a Top Safety Theme

2. Falls, Trips and Slips

Slips, trips, and the resulting falls are common workplace injuries, and a critical safety training theme, often due to poor housekeeping practices. Safe Work Australia reports that in 2013-14, 30% of falls were from working off a ladder. Serious injury can occur from falls of less than 2 metres so the potential risk of a fall of any distance, even a trip or slip, should be considered and action taken to reduce the likelihood of injury.

What Should be Done to Prevent Slips, Trips and Falls?

There are several ways that you can minimise the risk of a slip, trip or fall:

- Only keep frequently used tools in your work area.

- Floors around benches and machinery must be kept clear.

- Always keep your work area tidy by storing materials and equipment neatly,

- Keep extension leads off the ground by using cable stands, and

- Regularly dispose of waste material and rubbish in appropriate bins.

Tap into Safety Training Courses That Address Slips, Trips and Falls

We have developed two out of the box safety training courses that include training on the safety theme of slips, trips and falls.

- Stock Picking Warehouse

- Working at Height in Commercial Construction

- General Safety Induction

- Chemical Spills and Clean Up

See our article, What Can We Do To Prevent Fall From Height Risks?

Contact Us for more information.

In Conclusion

This article unpicked the top four causes of fatalities and injuries in the construction industry to provide some tips to address the problems. Managing workplace hazards in the construction industry is a complex issue due to the changing nature of the work environment on construction sites. The construction sector had the 4th highest injury rate in 2012-13 and the 5th highest fatality rate across all industries in 2013-14. In 202o, vehicle collisions accounted for 43% of all injury fatalities.

Training, with a specific focus on the safety training themes of interaction with powered mobile plant, working at height, working around machinery and moving parts, and working with electricity should be the industry’s key focus. These safety themes should be followed up with instructions on manual handling and preventing workers from being hit by moving objects. In doing so, the construction industry and construction companies will start to address workplace hazards in the construction industry that often have severe consequences.

This article is also available on the Tap into Safety podcast.